- info@ydbvalves.com

- +91 80870 10270

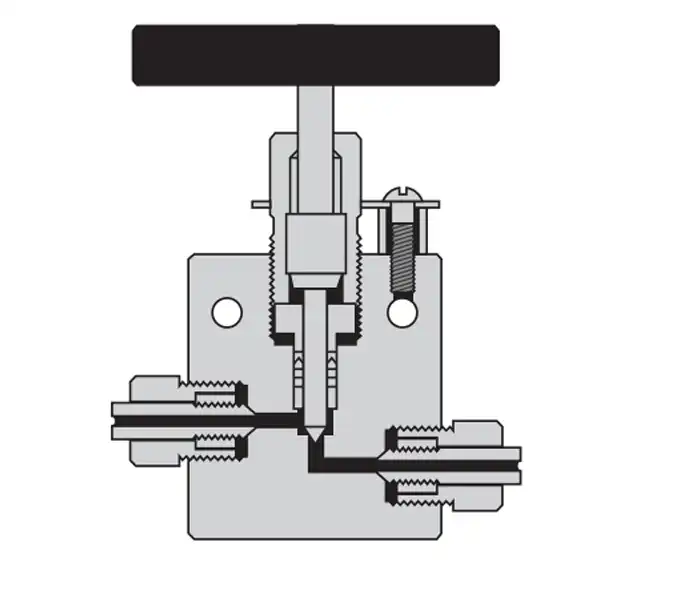

High-Pressure Needle Valve designed for pressures up to 40,000 PSI are specialized valves used in applications where extreme pressure control is critical. These valves feature a needle-like plunger that precisely regulates flow by controlling the size of the opening. The robust construction of these valves ensures reliable performance in high-pressure environments, making them suitable for demanding industrial applications.

These valves are typically made from high-strength materials like stainless steel or alloy steel to withstand corrosive and harsh environments. The fine-threaded stem and precision-machined body provide accurate flow control, leak-proof sealing, and exceptional durability.

The compact design, reliability, and precision make high-pressure needle valves ideal for systems requiring safe and efficient regulation of fluids or gases at very high pressures. Industries such as oil and gas, chemical processing, aerospace, and testing facilities commonly use these valves for critical operations.

High Pressure (coned & threaded) type connections for 9/16″ O.D. tubing.

Non-rotating tip stems are standard for on-off service andensure long life on valve seats. Regulating tip stems are available for all valves at no additional cost, add – REG to part number.

Glands and collars for tubing are supplied with each valve unless otherwise requested.

Materials include high tensile type 316 stainless steel bodies and hardened 17-4PH stainless steel lower section stems.

Packing Set Consists of multiple Teflon packing with nylon back up, with optional Viton (350°F), BUNA-N (200°F) and Grafoil (800°F) available at no additional cost.

Air operators for remote control operation are available for all valves.

Extreme temperatures can be accommodated using extended stuffing boxes.

Non-rotating stem tips

● Packing below stem threads

● Type 316 ss high tensile bodies

● Positive gland lock device

● No stem adjustment needed

● Black T-handles or choice of 4 colors

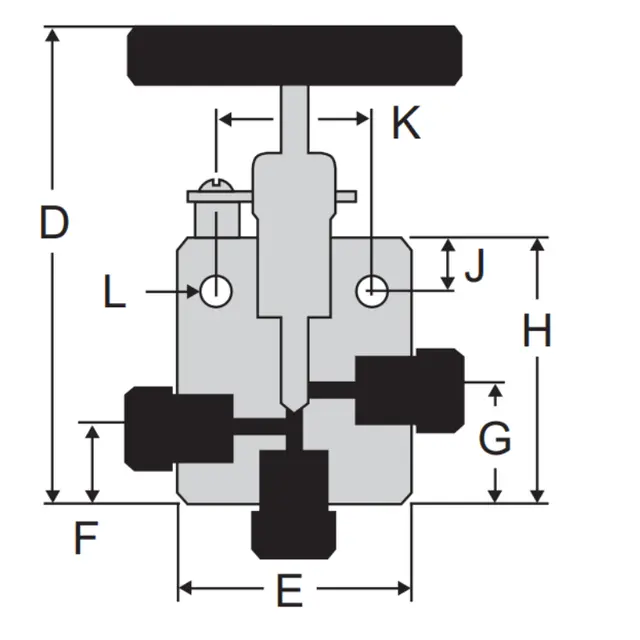

| Tubing | PSI | Connection | orifice | D | E | F | G | H | J | K | L | Thk | PART NO. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 9/16″ O.D. | 40,000 | HF9 | 1/8″ | 5-5/8″ | 2-5/8″ | 1″ | 1-7/16″ | 2-7/8″ | 1/2″ | 1-5/8″ | 7/32″ | 1-1/2″ | HPNV-40K-9T |

| Tubing | PSI | Connection | orifice | D | E | F | G | H | J | K | L | Thk | PART NO. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 9/16″ O.D. | 40,000 | HF9 | 1/8″ | 5-5/8″ | 2-5/8″ | – | 1-7/16″ | 2-7/8″ | 1/2″ | 1-5/8″ | 7/32″ | 1-1/2″ | HPANV-40K-9T |

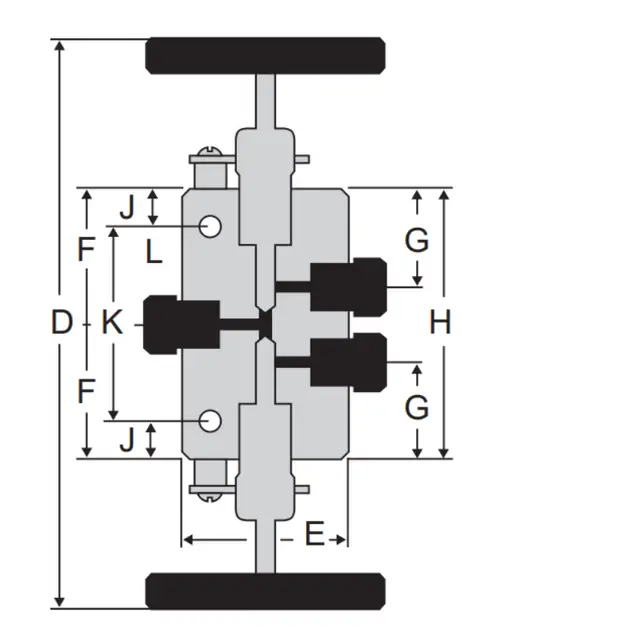

| Tubing | PSI | Connection | orifice | D | E | F | G | H | J | K | L | Thk | PART NO. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 9/16″ O.D. | 40,000 | HF9 | 1/8″ | 6-1/4″ | 2-5/8″ | 1-7/16″ | 1-7/8″ | 3-5/16″ | 1/2″ | 1-5/8″ | 7/32″ | 1-1/2″ | HP3NV2-40K-9T |

| Tubing | PSI | Connection | orifice | D | E | F | G | H | J | K | L | Thk | PART NO. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 9/16″ O.D. | 40,000 | HF9 | 1/8″ | 5-5/8″ | 2-5/8″ | 1-7/16″ | 1-7/16″ | 2-7/8″ | 1/2″ | 1-5/8″ | 7/32″ | 1-1/2″ | HP3NV1-40K-9T |

| Tubing | PSI | Connection | orifice | D | E | F | G | H | J | K | L | Thk | PART NO. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 9/16″ O.D. | 40,000 | HF9 | 1/8″ | 9-7/8″ | 2-5/8″ | 2-3/16″ | 1-7/16″ | 4-3/8″ | 1/2″ | 3-3/8″ | 7/32″ | 1-1/2″ | HP32NV-40K-9T |

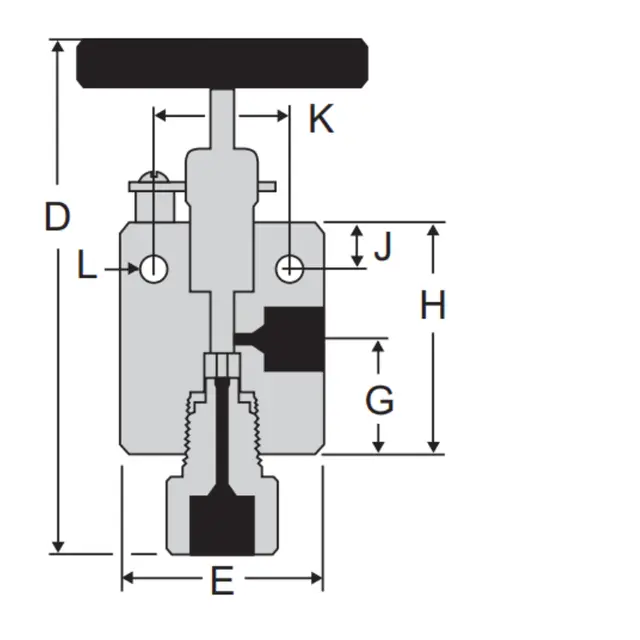

| Tubing | PSI | Connection | orifice | D | E | F | G | H | J | K | L | Thk | PART NO. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 9/16″ O.D. | 40,000 | HF9 | 1/8″ | 6-3/8″ | 2-5/8″ | – | 1-7/16″ | 2-7/8″ | 1/2″ | 1-5/8″ | 7/32″ | 1-1/2″ | HPNVR-40K-9T |

Explore our range of needle valves categorized by pressure rating:

Robust two-way shut-off valve with coned and threaded connections. Ideal for moderate high-pressure applications with excellent control and longevity.

A trusted solution for higher pressure systems. Designed with non-rotating stem tip and secure packing for enhanced leak prevention.

Top-tier valve in the HP series, capable of handling extreme pressures with reinforced construction, corrosion resistance, and thermal stability.

A pioneer manufacturer & supplier company having good experience in the designing and manufacturing of a new concept instrumentation Valves

Head Office :

Y-21, Khan Real Industrial Estate,

N. H. 08, Pelhar, Vasai Phata,

Vasai East, Palghar – 401208. INDIA

Email :

info@ydbvalves.com

Contact:

+91- 80 8701 0270