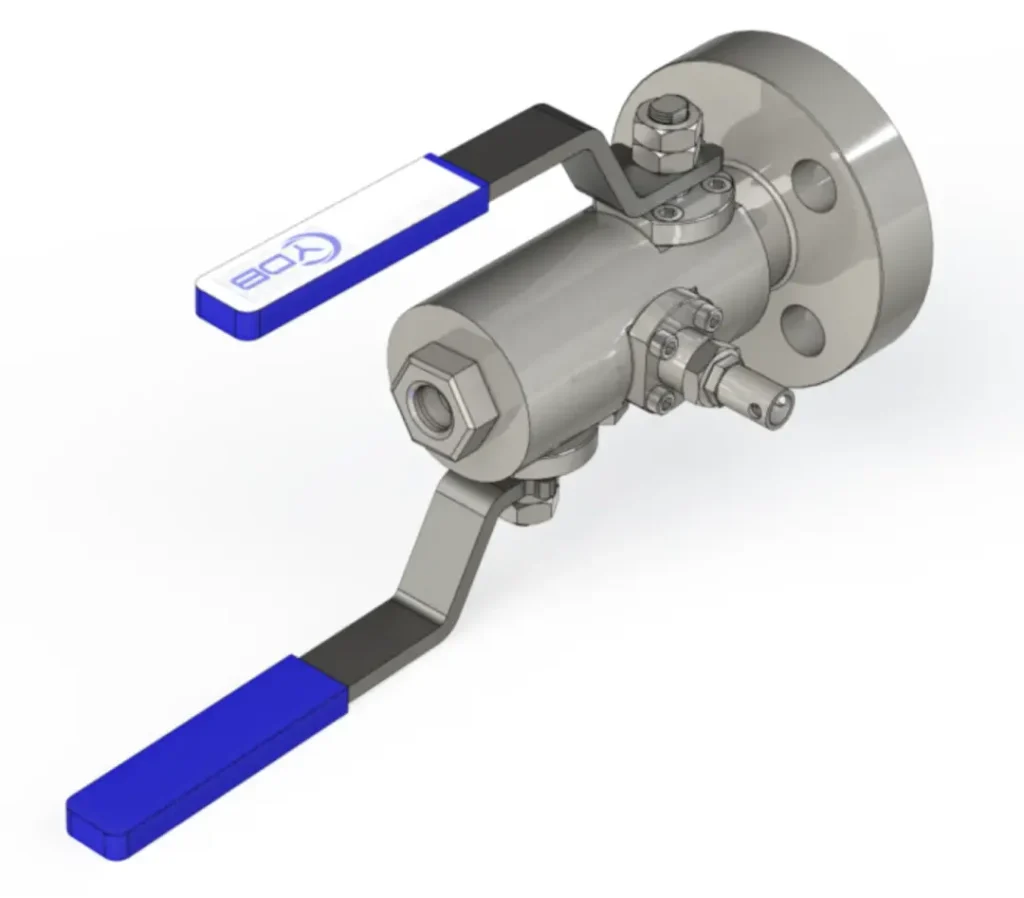

Injection Quill DBB Valve

Injection Quill DBB Valve

Introduction

In most modern applications there is often a requirement to take a sample of the process fluid or inject a particular chemical directly into the process stream at full operating pressures and temperatures

To meet this requirement then any of the YDB Valve ranges of Double Block and Bleed Valve including one piece body DBB, Modular Type, Monoflange Valve and Manifold Valve can be fitted with either an Injection Quill or Sampling Probe whilst retaining the wide choice of options available in each range.

Probes and Quills extend into the process medium and are designed to meet the individual application requirements. Units can be fitted with an Integral Check Valve to prevent back flow into the process stream.

Key Features

Built-in injection quill ensures accurate chemical dosing

Compact single-body design reduces weight and leak paths

Withstands corrosive fluids and high-pressure applications

Custom lengths and tip designs available

Suitable for both horizontal and vertical pipe installations

Fire-safe, anti-blowout stem, and leak-proof performance

Technical Specifications

The Injection Quill DBB Valve is a specialized equipment designed to inject chemicals or fluids into pipelines or process systems with enhanced safety and precision. It features a double block and bleed configuration, ensuring reliable isolation and safe venting of trapped pressure during injection operations.

The injection quill component extends into the pipeline, delivering the injected fluid directly into the flow stream to optimize mixing and distribution. Its robust construction and corrosion-resistant materials make it suitable for handling harsh chemicals and operating under high-pressure and high-temperature conditions.

Injection Quills

In many applications there is a need to inject chemicals such as de-waxing, de-icing or de-foaming agents into the process stream to facilitate a free flow of the process media.

The Injection Quill length (L) is manufactured to suit customer requirements. The Injection Nozzle is a 3mm diameter hole and other options available

Using the primary and secondary isolation valves the required chemical is injected directly into the process stream. It is usual for Injection Valves to be fitted witha non-return checkvalve that only opens when chemicals are injected into the process line thus preventing back flow out of the process stream.

Sampling Probes

Typically the need would be to allow a small process sample to be removed for evaluation under full system pressure.

Usually this is achieved by opening and closing of the primary isolation valve thus trapping a sample of the process fluid between the primary and secondary isolation valves. Using the vent valve this sample can then be safely vented off at reduced pressure.

Alternatively if larger samples are required then this can be achieved by use of the primary and secondary isolation valves with an optional Non Return Check Valve being fitted to prevent back flow into the process stream.

Non Return Valve

A high integrity full bore non-return valve, which can be fitted internally or externally, eliminates the risk of back flow into or out of the process stream. The design uses a spring loaded poppet to ensure leak proof performance and has standard cracking pressure of 10 psig although other cracking pressures can be supplied.

Construction

The Quill / Probe can be manufactured in several ways to suit the users’ requirement:

- The outlet flange and the probe can be made from a single one piece forging or from forged barstock.

- The Quill / Probe is manufactured from forged barstock which is then screwed and torqued into the outlet flange. If required the probe can also be seam welded to provide added strength.

- The Quill / Probe can be socket welded into the outlet flange.

Applications

The Double Block & Bleed Valve ensures safe isolation and controlled pressure venting in high-pressure pipelines and offshore platforms, enhancing safety and operational efficiency.

Used in chemical plants for handling hazardous fluids, the Double Block & Bleed Valve provides secure isolation and safe venting, reducing the risk of leaks and contamination.

In power plants, the Double Block & Bleed Valve ensures secure isolation of steam or cooling water systems and allows safe depressurization during maintenance.

The Double Block & Bleed Valve is used in petrochemical facilities for isolating and venting pressurized fluids or gases, ensuring system integrity and worker safety.

In marine applications, the Double Block & Bleed Valve is critical for isolating and venting fluid and gas systems aboard ships, ensuring operational reliability and safety.

Custom-engineered valve solutions for industrial fluid control.

Related Products

DBB Bleed Valve

Compact valve with two isolation ball/needle valves and a central bleed valve—ideal for direct mounting and small footprint applications.

Integral DBB Valve

All-in-one design combining isolation and bleed functionality in a single forged body. Reduces weight, installation time, and leak paths.

Monoflange Valve

Single flange-mounted solution with multiple isolation stages. Commonly used for pressure instrumentation, measurement, and sampling.