Ball Valves

Introduction

Reliable Isolation for High-Performance Applications

Ball Valves are robust shutoff solutions ideal for controlling fluid flow in critical applications across oil & gas, petrochemical, power, and process industries. Engineered for reliability, our valves are designed to deliver leak-proof performance and long service life, even in harsh conditions.

Key Features

2-piece & 3-piece forged and cast construction

Blow-out proof stem design

Antistatic device for fire-safe operation

Full bore & reduced bore options

Fire-safe & anti-static design compliant with API 607 / ISO 10497

Trunnion or floating ball configurations

High pressure & high-temperature capability

Available with manual, gear, pneumatic, or electric actuators

Applications

Oil & Gas Pipelines

Chemical & Petrochemical Plants

Power Plants

Refineries

Water Treatment & Distribution

Material Options

ASTM A105 (Carbon Steel)

ASTM A350 LF2 (Low Temperature Carbon Steel)

ASTM A182 F304 / F316 (Stainless Steel)

ASTM A182 F51 / F53 (Duplex & Super Duplex Steel)

ASTM A217 WC6 / WC9 (Alloy Steel)

ASTM A351 CF8 / CF8M (Cast Stainless Steel)

Monel, Hastelloy, Inconel (on request)

ASTM A182 F304 / F316 (SS)

ASTM A182 F6a (13% Cr Steel)

ASTM A182 F51 (Duplex Steel)

ENP / Hard Chrome Plated options available

Tungsten Carbide Coated (for abrasive service)

PTFE (Polytetrafluoroethylene)

RPTFE (Reinforced PTFE)

PEEK (Polyetheretherketone)

Devlon, Nylon, Delrin

Metal-to-Metal seating (for fire-safe or high-temp applications)

Graphite

PTFE

Viton

NBR / HNBR

EPDM

Metal Spiral Wound Gaskets (for fire-safe)

Operating Conditions

| Parameter | Value |

|---|---|

| Pressure Ratings | 150# to 2500# |

| Temperature Range | -46°C to +538°C |

| Size Range | ½” to 24” (Custom available) |

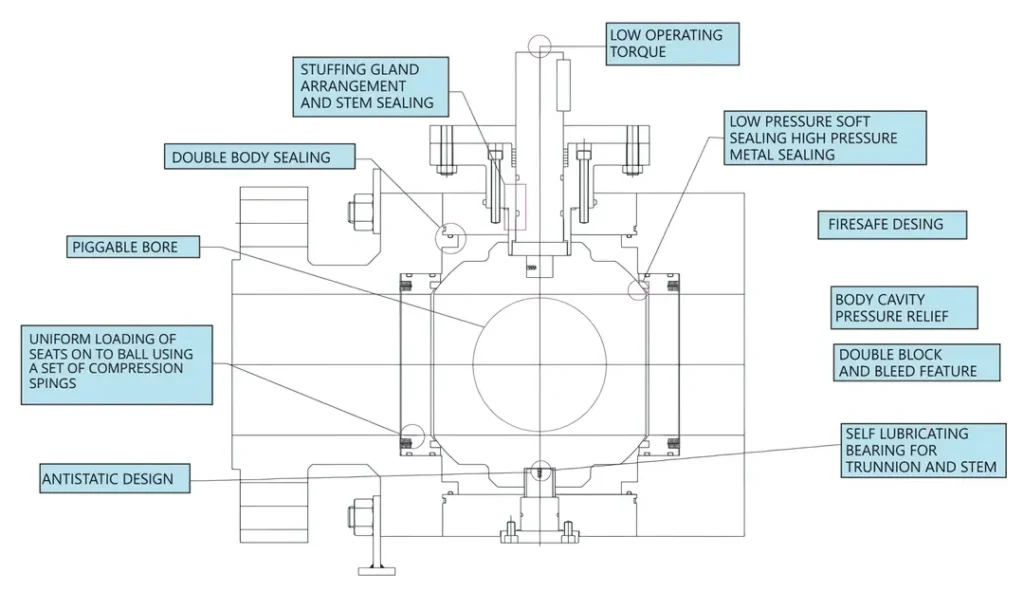

Trunnion Mounted Ball Valve

Design Features

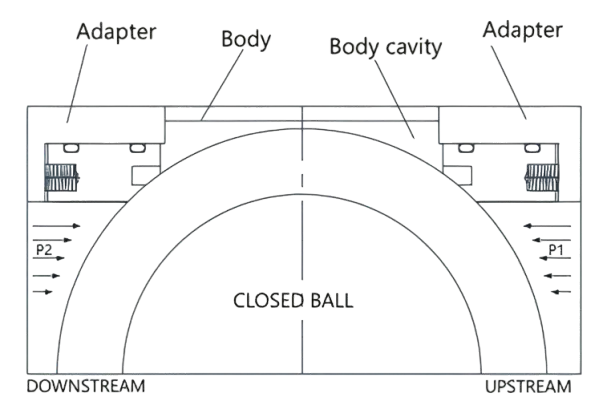

Double Block & Bleed

Spring loaded floating seats maintain contact with the ball and provide tight shut off even at low pressure differential. Independent sealing of upstream and downstream sides facilities draining of fluid from the body cavity, and thus the double block and bleed operation.

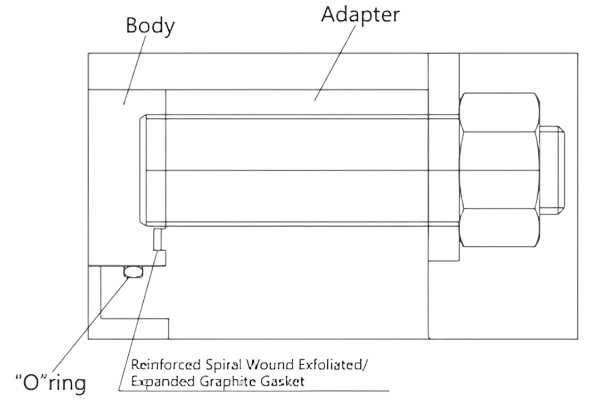

Double Body Sealing

Spring loaded floating seats maintain contact with the ball and provide tight shut off even at low pressure differential. Independent sealing of upstream and downstream sides facilities draining of fluid from the body cavity, and thus the double block and bleed operation.

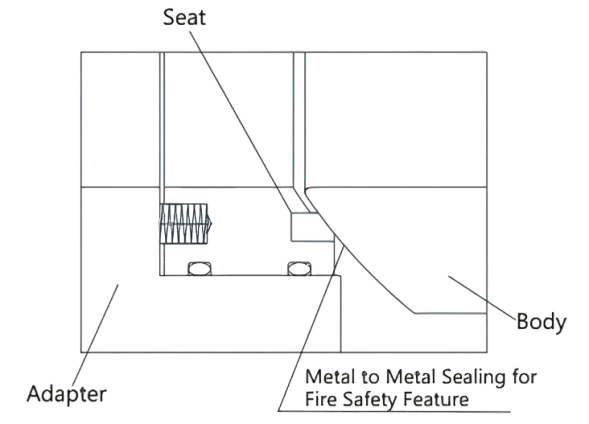

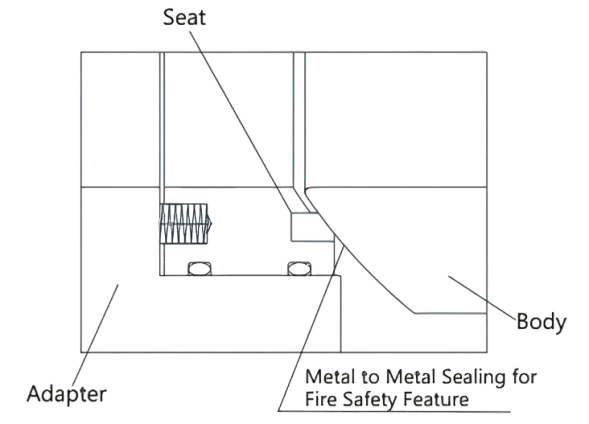

Fire Safe Design

In the event of fire, soft insert gets burnt and spring loaded seats ensure metal to metal sealing.

Multiple Stem Sealing

A triple sealing arrangement in stem area prevents leakage to atmosphere. It includes double sealing with O-ring and graphite seal at the top of stem housing. The blow out proof stem enables positive stem retention.

Technical Specifications

Within Given Tolerances By Closely Monitoring Critical Dimensions, Surface Finishes, Run Out, Sharp Edges Etc. After Referring And Meeting The Requirements As Per Drawing, Under Rigid Quality Controlled Procedures Approved To ISO 9001: 2015 Which Ensures Consistent Quality and High Performance Products.

Design & Testing Standards

- YDB Valves are designed and manufactured as per ASME B 16.34, API 6D & BS 5351/BS EN ISO 17292. These standards cover pressure – Temperature ratings, minmum shell thickness, bore diameter for each size/ class.

- Valve body and trim can be offered as per NACE MR 01-75 compliant.

- Castings inspection as per MSS-SP 53, 54, 55, 59, 93 & 94

- Actuator mounting pad on the valve as per ISO 5211

- Other applicable standards:

- Valve Bore: API 6D

- Face to Face: ASME B 16.10/API 6D

- Flange dimensions: ASME B16.5/B16.47 / MSS SP 44

- Butt weld valve ends: ASME B 16.25/B 31.3/B 31.4/B 31.8

- Pressure tests: API 6D/API 6FA/BS EN 12266-1 & 2

- Fire safe test: API 607/ API 6FA/BS 6755 Part II/ BS EN ISO 10497

- Drain / Vent/ Bypass: MSS SP 46/API 6D