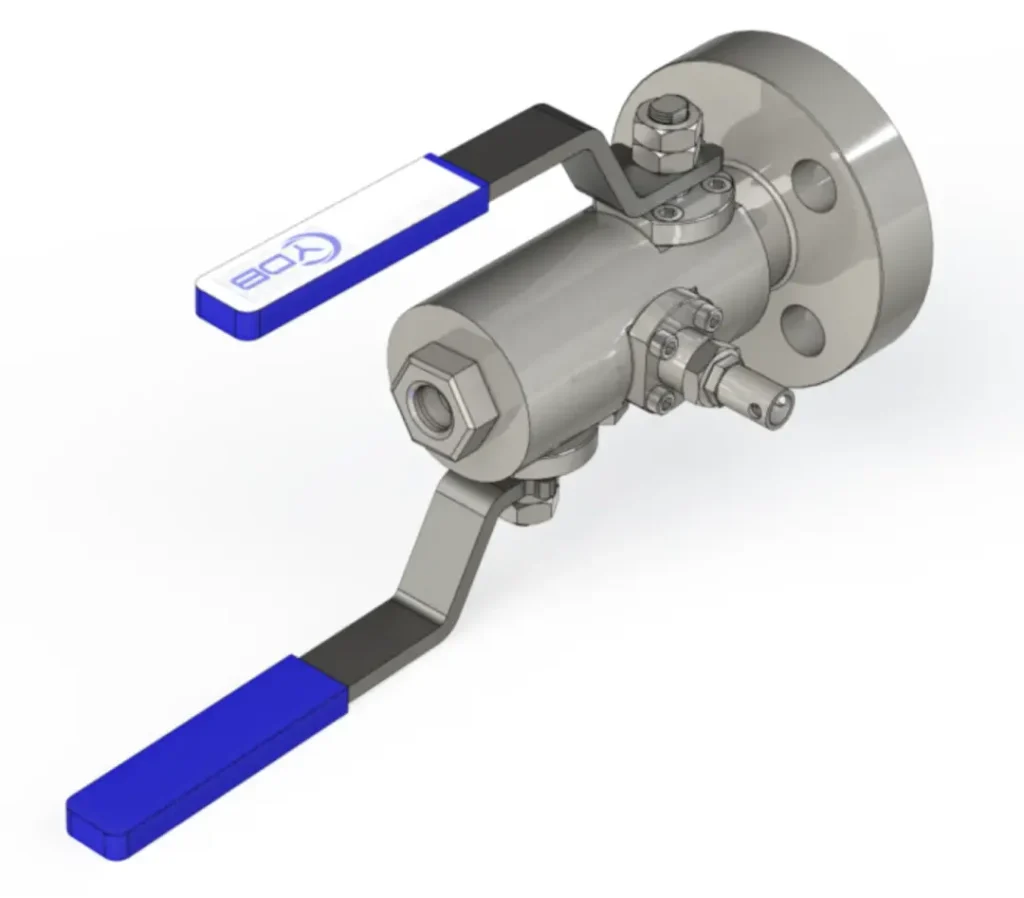

DBB Bleed Valves

Double Block & Bleed

Introduction

A Double Block & Bleed is a specialized valve solution designed to provide maximum isolation and safe pressure venting in critical systems. It combines two isolation valves and a bleed valve into a single, compact unit, allowing users to safely depressurize and drain trapped fluids or gases between the two isolation points. This valve is engineered for high-performance applications, offering a reliable and leak-tight sealing mechanism.

These valves are essential in industries where high-pressure, high-temperature, or hazardous fluid systems require safe and efficient isolation and venting. With robust construction from corrosion-resistant materials such as stainless steel or alloy steel, the Double Block & Bleed Valve is ideal for applications in oil and gas pipelines, chemical processing, power generation, and marine systems.

Why Choose Our DBB Bleed Valves?

- Compact design for space-constrained installations

- Suitable for pressure ratings up to 10,000 psi

- Available in various bore sizes

- Full compliance with ASME and API standards

- Anti-static and fire-safe design

- Reduced potential leak paths

- Wide material compatibility (SS316, Duplex, etc.)

Technical Specifications

| Parameter | Value |

|---|---|

| Type | DBB Bleed Valve |

| Bore Size | 9.5mm to 25mm (Options Available) |

| Pressure | Up to 10,000 PSI |

| Connections | Flanged / Threaded |

| Body Material | SS316 / Duplex / Other on Request |

Design & Testing Standards

- YDB Valves are designed and manufactured as per ASME B 16.34, API 6D & BS 5351/BS EN ISO 17292. These standards cover pressure – Temperature ratings, minmum shell thickness, bore diameter for each size/ class.

- Valve body and trim can be offered as per NACE MR 01-75 compliant.

- Castings inspection as per MSS-SP 53, 54, 55, 59, 93 & 94

- Actuator mounting pad on the valve as per ISO 5211

- Other applicable standards:

- Valve Bore: API 6D

- Face to Face: ASME B 16.10/API 6D

- Flange dimensions: ASME B16.5/B16.47 / MSS SP 44

- Butt weld valve ends: ASME B 16.25/B 31.3/B 31.4/B 31.8

- Pressure tests: API 6D/API 6FA/BS EN 12266-1 & 2

- Fire safe test: API 607/ API 6FA/BS 6755 Part II/ BS EN ISO 10497

- Drain / Vent/ Bypass: MSS SP 46/API 6D

Applications

The Double Block & Bleed Valve ensures safe isolation and controlled pressure venting in high-pressure pipelines and offshore platforms, enhancing safety and operational efficiency.

Used in chemical plants for handling hazardous fluids, the Double Block & Bleed Valve provides secure isolation and safe venting, reducing the risk of leaks and contamination.

In power plants, the Double Block & Bleed Valve ensures secure isolation of steam or cooling water systems and allows safe depressurization during maintenance.

The Double Block & Bleed Valve is used in petrochemical facilities for isolating and venting pressurized fluids or gases, ensuring system integrity and worker safety.

In marine applications, the Double Block & Bleed Valve is critical for isolating and venting fluid and gas systems aboard ships, ensuring operational reliability and safety.

Custom-engineered valve solutions for industrial fluid control.

Related Products

Integral DBB Valve

All-in-one design combining isolation and bleed functionality in a single forged body. Reduces weight, installation time, and leak paths.

Injection Quill DBB Valve

Designed for injecting chemicals into the process line with safety isolation and backflow prevention. Suitable for high-pressure pipelines.

Monoflange Valve

Single flange-mounted solution with multiple isolation stages. Commonly used for pressure instrumentation, measurement, and sampling.