- info@ydbvalves.com

- +91 80870 10270

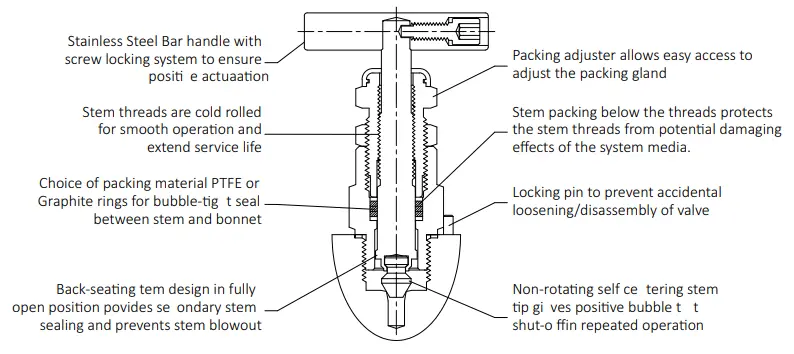

The YNV01 Series Instrumentation Needle Valve from YDB Valve is designed for precise flow control in high-pressure and high-accuracy applications. With a finely threaded stem and robust stainless steel construction, it provides smooth, gradual regulation of flow, making it ideal for instrumentation panels, gas sampling systems, and chemical injection lines. The compact design and high-pressure capability ensure reliable operation even in demanding environments.

Engineered for versatility, the YNV01 offers various end connections, seat materials, and pressure ratings to suit a wide range of media and applications. Its leak-tight shut-off and corrosion-resistant body ensure long service life with minimal maintenance. Whether installed in laboratories, refineries, or industrial process lines, the YNV01 delivers reliable performance, safety, and precision control where it matters most.

Control of hydrocarbon fluids, sampling, and pressure measurement systems.

Flow regulation in filtration, sampling, and chemical dosing systems.

Steam systems, pressure monitoring, and boiler instrumentation.

Flow control in chemical dosing, mixing systems, and sampling lines.

Sterile fluid control and pressure monitoring in cleanroom environments.

Control of slurry, reagent dosing, and pressure monitoring systems.

The Temperature and Pressure rating for a standard valve with PTFE packing

| Temperature | Pressure | |

|---|---|---|

| psig | bar | |

| -54°C to 38°C | 6000 | 408 |

| -54°C to 93°C | 5160 | 351 |

| -54°C to 148°C | 4660 | 317 |

| -54°C to 204°C | 4280 | 291 |

| -54°C to 232°C | 4130 | 289 |

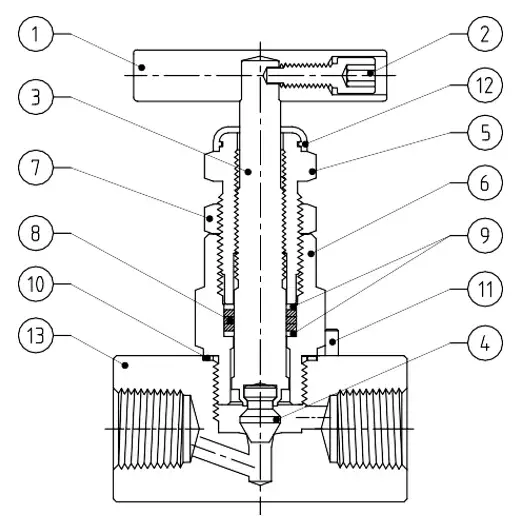

| Sr No. | Description | Material |

|---|---|---|

| 1. | Bar Handle | SS316 |

| 2. | Set Screw | SS316 |

| 3. | Stem | SS316 |

| 4. | Stem Tip | SS316 |

| 5. | Packing Bolt | SS316 |

| 6. | Lower Bonnet | SS316 |

| 7. | Lock Nut | SS316 |

| 8. | Packing | PTFE |

| 9. | Packing Washer | SS316 |

| 10. | Washer | SS316 |

| 11. | Lock Pin | SS316 |

| 12. | Dust Cap | PVC |

| 13. | Valve Body | SS316 |

YDB Needle Valves are available with choice of optional stem to provide greater flexibility.

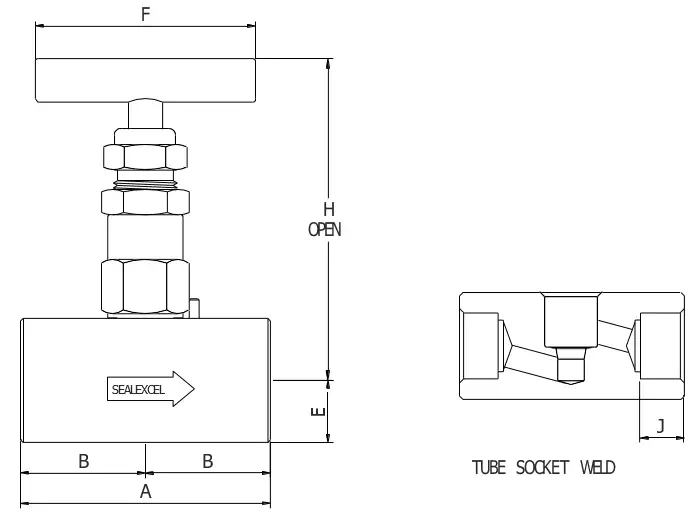

| END CONNECTOR | DIMENSION (MM) | PART NO. | ||||||

|---|---|---|---|---|---|---|---|---|

| INLET | OUTLET | A | B | C | D | E | F | |

| 1/4″ ODT | 1/4″ ODT | 73.0 | 36.5 | 25.4 | 4.3 | 73.0 | 54.0 | YNV01-TT4 |

| 3/8″ ODT | 3/8″ ODT | 73.0 | 36.5 | 28.6 | 4.3 | 88.0 | 60.0 | YNV01-TT6 |

| 1/2″ ODT | 1/2″ ODT | 77.8 | 38.9 | 28.6 | 6.4 | 88.0 | 60.0 | YNV01-TT8 |

| 3/4″ ODT | 3/4″ ODT | 85.2 | 42.9 | 31.8 | 6.4 | 114.0 | 67.0 | YNV01-TT12 |

| 6MM ODT | 6MM ODT | 73.0 | 36.5 | 25.4 | 4.3 | 73.0 | 54.0 | YNV01-TT6M |

| 8MM ODT | 8MM ODT | 73.0 | 36.5 | 25.4 | 4.3 | 73.0 | 54.0 | YNV01-TT8M |

| 10MM ODT | 10MM ODT | 73.0 | 36.5 | 28.6 | 6.4 | 88.0 | 60.0 | YNV01-TT10M |

| 12MM ODT | 12MM ODT | 77.8 | 38.9 | 28.6 | 6.4 | 88.0 | 60.0 | YNV01-TT12M |

| 1/8″ FNPT | 1/8″ FNPT | 57.2 | 28.6 | 25.4 | 4.3 | 73.0 | 52.0 | YNV01-FF2N |

| 1/4″ FNPT | 1/4″ FNPT | 57.2 | 28.6 | 25.4 | 4.3 | 73.0 | 54.0 | YNV01-FF4N |

| 3/8″ FNPT | 3/8″ FNPT | 57.2 | 28.6 | 28.6 | 6.4 | 88.0 | 60.0 | YNV01-FF6N |

| 1/2″ FNPT | 1/2″ FNPT | 66.6 | 33.3 | 31.8 | 6.4 | 88.0 | 67.0 | YNV01-FF8N |

| 3/4″ FNPT | 3/4″ FNPT | 69.8 | 34.9 | 35.0 | 9.5 | 114 | 67.0 | YNV01-FF12N |

| 1″ FNPT | 1″ FNPT | 82.6 | 41.3 | 45.0 | 9.5 | 122 | 73.0 | YNV01-FF16N |

| 1/4″ MNPT | 1/4″ MNPT | 57.2 | 28.6 | 25.4 | 4.3 | 73.0 | 54.0 | YNV01-MM4N |

| 1/4″ MNPT | 1/4″ FNPT | 60.2 | 30.1 | 25.4 | 4.3 | 73.0 | 54.0 | YNV01-MF4N |

| 1/2″ MNPT | 1/2″ FNPT | 69.8 | 34.9 | 31.8 | 6.4 | 88.0 | 60.0 | YNV01-MF8N |

| 3/4″ MNPT | 3/4″ MNPT | 76.2 | 38.1 | 35.0 | 9.5 | 114.0 | 67.0 | YNV01-MF12N |

| 1″ MNPT | 1″ FNPT | 85.8 | 42.9 | 45.0 | 9.5 | 122.0 | 73.0 | YNV01-MF16N |

| 1/4″ TSW | 1/4″ TSW | 57.2 | 28.6 | 25.4 | 4.3 | 73.0 | 54.0 | YNV01-TSW4 |

| 3/8″ TSW | 3/8″ TSW | 57.2 | 28.6 | 28.6 | 6.4 | 88.0 | 60.0 | YNV01-TSW6 |

| 1/2″ TSW | 1/2″ TSW | 66.6 | 33.3 | 28.6 | 6.4 | 88.0 | 60.0 | YNV01-TSW8 |

| 3/4″ TSW | 3/4″ TSW | 69.8 | 34.9 | 31.8 | 9.5 | 114.0 | 67.0 | YNV01-TSW12 |

– Dimensions shown with YDB ODT Nut are finger tight.

– Dimensions are for reference only and subject to change

A pioneer manufacturer & supplier company having good experience in the designing and manufacturing of a new concept instrumentation Valves

Head Office :

Y-21, Khan Real Industrial Estate,

N. H. 08, Pelhar, Vasai Phata,

Vasai East, Palghar – 401208. INDIA

Email :

info@ydbvalves.com

Contact:

+91- 80 8701 0270