- info@ydbvalves.com

- +91 80870 10270

2 Valve Manifolds are critical components in industrial instrumentation systems that are used to isolate and control the flow of pressure to a measurement instrument, such as pressure gauges or transmitters. These manifolds provide a simple yet effective solution for isolating the instrument from the process, allowing for easier maintenance and calibration without disrupting the entire system.

A 2 Valve Manifolds typically features two valves—an isolation valve and a vent valve—that allow the operator to isolate the instrument from the process line and vent any pressure safely. This design is commonly used for pressure measurement applications and is valued for its simplicity, reliability, and cost-effectiveness. The 2-valve manifold is the most basic manifold configuration, and it is often used where minimal functionality is needed, such as in situations where the process does not require equalizing or differential pressure measurement.

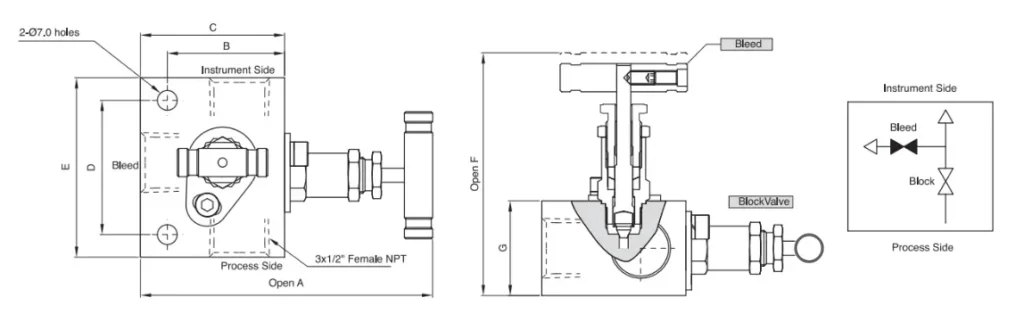

| Part Number | End Connections | Weight Dimensions | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Process | Instrument | Bleed | A | B | C | D | E | F | G | |

| YM2V-F8N | 1/2″ Female NPT | 103.5 | 41.5 | 51 | 47.5 | 63.5 | 85.9 | 33.5 | ||

Dimensions are for reference only and are subject to change.

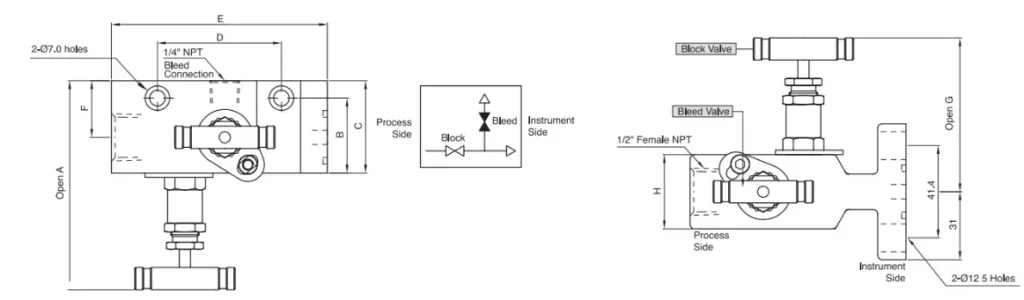

| Part Number | End Connections | Weight Dimensions | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Process | Instrument | Bleed | A | B | C | D | E | F | G | |

| YM2V-F8N | 1/2″ Female NPT | Flange | 1/4″ Female NPT | 103.5 | 41.5 | 51 | 47.5 | 63.5 | 85.9 | 33.5 |

Dimensions are for reference only and are subject to change.

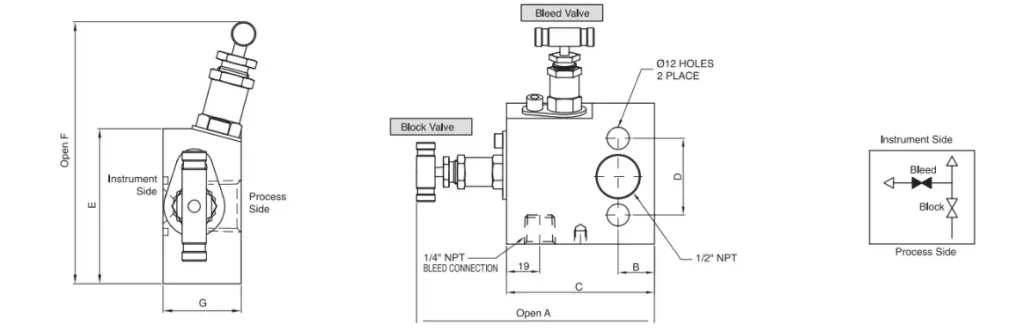

| Part Number | End Connections | Weight Dimensions | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Process | Instrument | Bleed | A | B | C | D | E | F | G | |

| YM2V-F8N | 1/2″ Female NPT | Flange | 1/4″ Female NPT | 116.0 | 17.0 | 63.5 | 41.4 | 63.5 | 115.0 | 23.6 |

Dimensions are for reference only and are subject to change.

A pioneer manufacturer & supplier company having good experience in the designing and manufacturing of a new concept instrumentation Valves

Head Office :

Y-21, Khan Real Industrial Estate,

N. H. 08, Pelhar, Vasai Phata,

Vasai East, Palghar – 401208. INDIA

Email :

info@ydbvalves.com

Contact:

+91- 80 8701 0270