- info@ydbvalves.com

- +91 80870 10270

Instrumentation Check Valve are precision-engineered devices designed to allow fluid or gas flow in one direction while preventing reverse flow. These valves are critical in protecting sensitive instrumentation and system components from potential damage caused by backflow or reverse pressure.

Instrumentation Check valve operate automatically based on pressure differentials, requiring no external actuation. They are commonly used in applications involving gases, liquids, or aggressive chemicals, and are constructed using materials such as stainless steel, Hastelloy, or other corrosion-resistant alloys to ensure reliability and durability in demanding environments.

Control of hydrocarbon fluids, sampling, and pressure measurement systems.

Flow regulation in filtration, sampling, and chemical dosing systems.

Steam systems, pressure monitoring, and boiler instrumentation.

Flow control in chemical dosing, mixing systems, and sampling lines.

Sterile fluid control and pressure monitoring in cleanroom environments.

Control of slurry, reagent dosing, and pressure monitoring systems.

Pressure Rating

| No. | Component | Material |

| 1 | Inlet Body | Stainless Steel 316 |

| 2 | Seal Ring | Viton |

| 3 | Poppet | Stainless Steel 316 |

| 4 | Spring | Stainless Steel |

| 5 | Outlet Body | Stainless Steel 316 |

| Size | Maximum Flow Coefficient (Cv) | Nominal Cracking Pressure psig (bar) | Downstream Pressure at 70G (20C) psig (bar) |

| 1/8″ | 0.10 | 1, 10, 25 ( 0.07, 0.69, 1.8) | 1000 (68.9) |

| 1/4″ | 0.47 | 1, 10, 25 ( 0.07, 0.69, 1.8) | 1000 (68.9) |

| 3/8″ | 1.47 | 1, 10, 25 ( 0.07, 0.69, 1.8) | 200 (13.7) |

| 1/2″ | 1.68 | 1, 10, 25 ( 0.07, 0.69, 1.8) | 200 (13.7) |

| 3/4″, 1″ | 4.48 | 1, 10, 25 ( 0.07, 0.69, 1.8) | 200 (13.7) |

For cracking pressure of 25 psig (1.8 bar), downstream pressure is 3000 psig (206 bar)

| O-Ring Material | Temperature Rating F(°C) |

| Buna – N | -10 to 250 (-23 to 121) |

| EPDM | -70 to 250 (-55 to 121) |

| Viton (Fluorocarbon) | -10 to 350 (-23 to 191) |

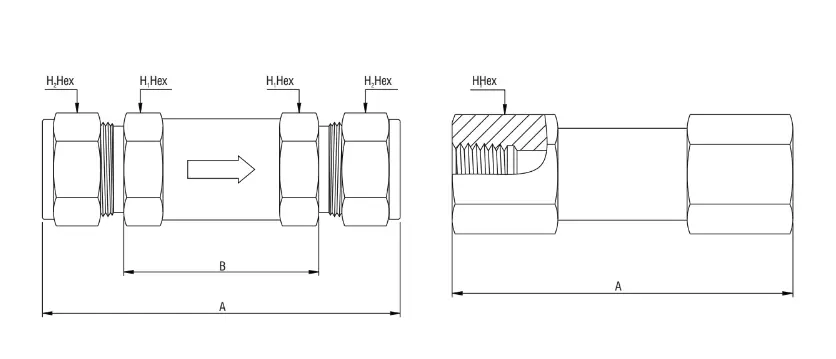

| END CONNECTOR | DIMENSION (mm) | PART NO. | ||||

| INLET | OUTLET | A | B | H | G | |

| 1/8″ ODT | 1/8″ ODT | 57.20 | 26.6 | 15.88 | 11.11 | YCV01 TT2 |

| 1/4″ ODT | 1/4″ ODT | 62.20 | 26.6 | 15.88 | 14.28 | YCV01 TT4 |

| 3/8″ ODT | 3/8″ ODT | 76.20 | 37.6 | 22.2 | 17.46 | YCV01 TT6 |

| 1/2″ ODT | 1/2″ ODT | 86.60 | 42.9 | 25.4 | 22.22 | YCV01 TT8 |

| 5/8″ ODT | 5/8″ ODT | 91.70 | 48.0 | 28.50 | 28.57 | YCV01 TT10 |

| 3/4″ ODT | 3/4″ ODT | 99.80 | 56.1 | 31.80 | 38.10 | YCV01 TT12 |

| 1″ ODT | 1″ ODT | 111.20 | 58.4 | 38.10 | 14.0 | YCV01 TT16 |

| 6mm ODT | 6mm ODT | 62.2 | 26.6 | 16.0 | 18.0 | YCV01 TT6M |

| 10mm ODT | 10mm ODT | 76.2 | 37.6 | 22.0 | 22.0 | YCV01 TT10M |

| 12mm ODT | 12mm ODT | 86.2 | 42.9 | 25.0 | 25.0 | YCV01 TT12M |

| 16mm ODT | 16mm ODT | 91.7 | 48 | 28.0 | YCV01 TT16M | |

| 1/8″ Female NPT | 1/8″ Female NPT | 50.00 | – | 15.88 | – | YCV01 FF2N |

| 1/4″ Female NPT | 1/4″ Female NPT | 57.10 | – | 19.05 | – | YCV01 FF4N |

| 3/8″ Female NPT | 3/8″ Female NPT | 73.90 | – | 22.2 | – | YCV01 FF6N |

| 1/2″ Female NPT | 1/2″ Female NPT | 90.60 | – | 27.00 | – | YCV01 FF8N |

| 3/4″ Female NPT | 3/4″ Female NPT | 104.00 | – | 31.80 | – | YCV01 FF12N |

| 1″ Female NPT | 1″ Female NPT | 123.00 | – | 41.27 | – | YCV01 FF16 |

| 1/8″ Male NPT | 1/8″ Male NPT | 44.5 | 24.4 | 15.88 | – | YCV01 MM2N |

| 1/4″ Male NPT | 1/4″ Male NPT | 54.0 | 24.7 | 15.88 | – | YCV01 MM4N |

| 3/8″ Male NPT | 3/8″ Male NPT | 71.4 | 43.0 | 22.2 | – | YCV01 MM6N |

| 1/2″ Male NPT | 1/2″ Male NPT | 80.3 | 42.2 | 22.2 | – | YCV01 MM8N |

| 3/4″ Male NPT | 3/4″ Male NPT | 104.00 | 65.8 | 31.8 | – | YCV01 MM12N |

| 1″ Male NPT | 1″ Male NPT | 114.8 | 67.3 | 35.0 | – | YCV01 MM16N |

Dimensions are for reference only and subject to change without notice

A pioneer manufacturer & supplier company having good experience in the designing and manufacturing of a new concept instrumentation Valves

Head Office :

Y-21, Khan Real Industrial Estate,

N. H. 08, Pelhar, Vasai Phata,

Vasai East, Palghar – 401208. INDIA

Email :

info@ydbvalves.com

Contact:

+91- 80 8701 0270