- info@ydbvalves.com

- +91 80870 10270

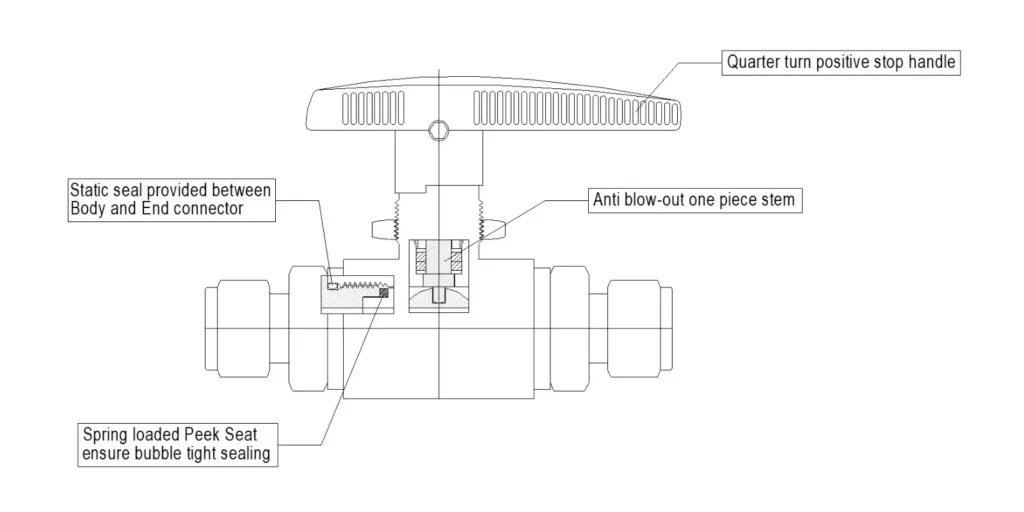

Instrumentation Ball Valve are precision-engineered valves designed to provide reliable control over fluid or gas flow in instrumentation and process control systems. These valves utilize a quarter-turn mechanism with a ball-shaped closure device featuring a bore through its center. When the ball is rotated, the bore aligns with the flow path to allow fluid passage or rotates perpendicular to block it, ensuring quick and efficient shutoff or flow regulation.

Instrumentation ball valve are typically constructed from high-grade materials like stainless steel, ensuring durability and resistance to corrosion in challenging environments. They are available in various sizes and configurations to accommodate diverse industrial applications, with some models offering multi-port options for enhanced flexibility.

Control of hydrocarbon fluids, sampling, and pressure measurement systems.

Flow regulation in filtration, sampling, and chemical dosing systems.

Steam systems, pressure monitoring, and boiler instrumentation.

Flow control in chemical dosing, mixing systems, and sampling lines.

Sterile fluid control and pressure monitoring in cleanroom environments.

Control of slurry, reagent dosing, and pressure monitoring systems.

Pressure Rating

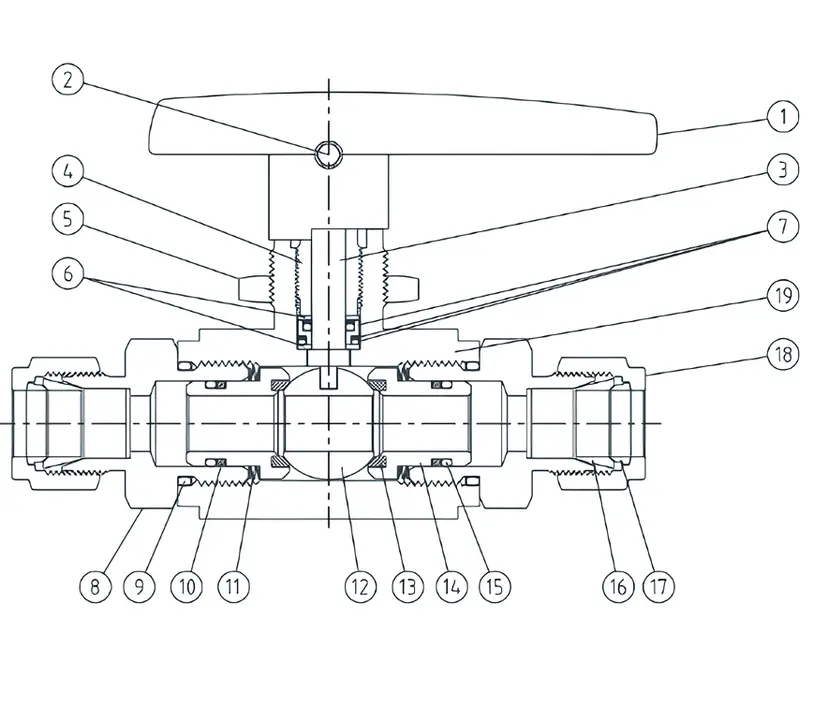

| Sr No | Description | Material |

| 1 | HANDLE | PHENOLIC NYLON |

| 2 | HANDLE LOCK SCREW | STAINLESS STEEL |

| 3 | VALVE STEM | SS316 |

| 4 | PACKING NUT | SS316 |

| 5 | PANEL NUT | SS316 |

| 6 | STEM WASHER | SS316 |

| 7 | STEM SEALING WITH | SS316 |

| ‘O’ Ring | VITON | |

| BACKUP WASHER | PTFE | |

| 8 | END CONNECTOR | SS316 |

| 9 | CONNECTOR ‘O’ RING | VITON |

| 10 | SEAT RETAINER BACKUP RING | PTFE |

| 11 | SPRING | STAINLESS STEEL |

| 12 | BALL | SS316 |

| 13 | VALVE SEAT | PEEK |

| 14 | SEAT RETAINER | SS316 |

| 15 | RETAINER ‘O’ RING | VITON |

| 16 | FRONT FERRULE | SS316 |

| 17 | BACK FERRULE | SS316 |

| 18 | FERRULE NUT | SS316 |

| 19 | VALVE BODY | SS316 |

A pioneer manufacturer & supplier company having good experience in the designing and manufacturing of a new concept instrumentation Valves

Head Office :

Y-21, Khan Real Industrial Estate,

N. H. 08, Pelhar, Vasai Phata,

Vasai East, Palghar – 401208. INDIA

Email :

info@ydbvalves.com

Contact:

+91- 80 8701 0270